编号 :

Hydrogen production 1200 ml/min PEM electrolyzer

零售价

市场价

重量

库存

隐藏域元素占位

- Product Description

-

Unit Parameters Remarks Hydrogen flow ml/min 1200 Error range ± 3% Oxygen flow ml/min 600 Error range ± 3% Water consumption ml/h ≯144 The water from both the hydrogen outlet and oxygen outlet returns to the water tank Water supply mode / Water pump circulation The flow rate of the water pump shall not be less than 2.4L/min Electrolytic mode / Pure water electrolysis No need to add alkaline solution, safe and reliable, easy to maintain Max. operating pressure MPa 0.1~1.3 Water quality requirement ppm ≤5 You can choose Yibao purified water, secondary distilled water, Watsons purified water, or deionized water Power

equirementsADC A 25 Constant current power supply VDC V 15 Dimensions

(length * width * depth)

mm ≯99*113*55 Excluding terminal blocks and connectors Weight kg 1.5~1.6 Other matters The size of the inlet and outlet pipes for hydrogen and oxygen in the electrolytic cell is 2 pipes Application area Hydrogen production machine, hydrogen generator, hydrogen oxygen generator, hydrogen rich water machine, hydrogen nourishing machine, hydrogen bath equipment, beauty instrument

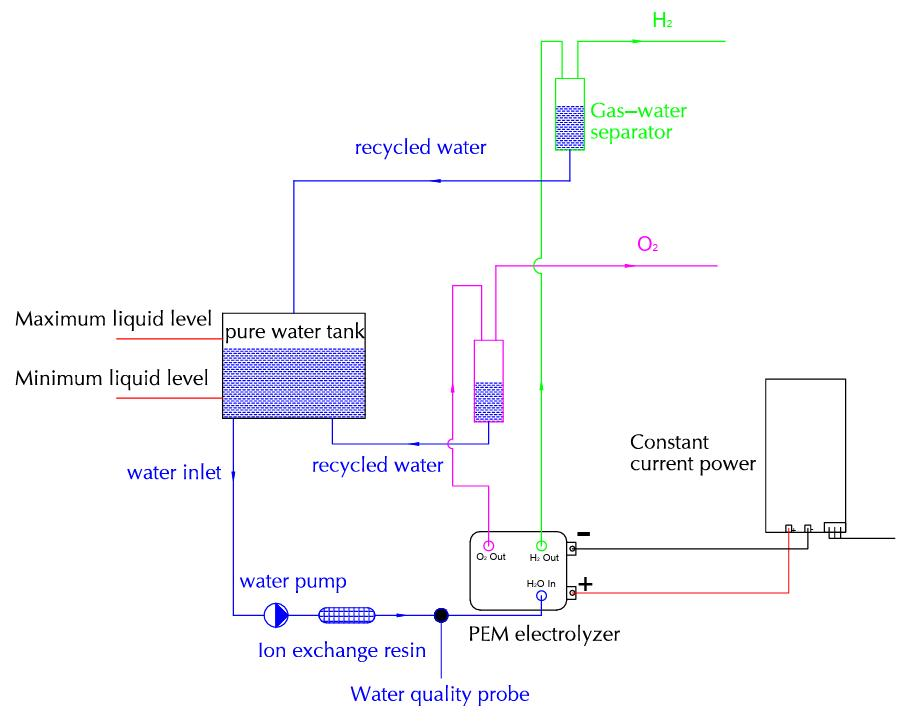

Three marks above the electrolyzer:

H2O In : Represents the water inlet, connected to the pure water tank outlet.

H2 Out: Represents the hydrogen outlet, connected to the hydrogen pipe.

O2 Out: Represents the outlet of oxygen and water, and the water coming out of the oxygen outlet is either connected to the water separator (water from the water separator is returned to the tank) or directly to the tank.Technical requirements

1.The electrolyzer should be used in strict accordance with the standard of pure water/deionized water, that is, the conductivity is less than 1 uS/cm. The water quality will directly determine the service life of the electrolyzer, so the machine must be equipped with ion exchange resin to ensure that the water quality is up tostandard, and the resin filter element is best placed between the water outlet of the pure tank and the water inlet of the electrolyzer .

2. The use of electrolyzer temperature range is 15~65 degrees Celsius. The starting temperature of the electrolyzer is recommended not to be lower than 15 ℃, and long-term low temperature starting will have a certain impact on the life of the electrolyzer. Recommended starting scheme: Control the power supply current output through the control board, the output current (such as 5A-10A-15A-20A)gradually rises, and finally stabilizes at the rated current 25A.

3. The electrolyzer is strictly prohibited to use water shortage, water shortage will cause the electrolyzer dry burning and damage.

4. The constant current power supply must be matched according to the voltage and current parameters of the electrolyzer. The mismatch of the power supply parameters will affect and damage the performance of the electrolyzer.

5. The anode and cathode of the electrolyzer can not be reversed, otherwise it will cause the electrolyzer to burn.

Precautions

1.The pipeline connection should be stable and reliable, with appropriate temperature resistance, pressure resistance, oxidation resistance, hydrolysis resistance, to prevent aging or falling off resulting in water or gas leakage. The material in contact with water must be resistant to corrosion, oxidation, and high temperature. lt is recommended to use Teflon materials as structural parts or pipes. lf metal materials are required, pure titanium is recommended.

2.The machine structure design should be reasonable to ensure the normal air flow to achieve good heat dissipation effect.

3. lt is recommended that the pure water tank is not less than 3500mL, the water tank needs to set the liquid level control device (minimum liquid level and maximum liquid level), the minimum liquid level of the water tank is not less than 1400mL.

4. The electrical components used should be safe enough and the connection process should be appropriate. The connection wire between the power supply and the electrolyzer must be tight and reliable, otherwise there are potential safety risks. The positive and negative wires of the power supply and the positive and negative terminals above the electrolyzer must be tightened otherwise a lot of heat will be generated, and there is a safety hazard

5. Storage requirements

1) it is strictly prohibited to pull off the plug of the electrolyzer for storage,which will cause water shortage and dry inside the electrolyzer, affecting the performance of the electrolyzer.

2) Storage date of the electrolyzer: if the electrolyzer has been stored for more than 120 days and is not used, it is recommended to remove the plug of the inlet and outlet of the electrolyzer, place the electrolyzer lying flat and inject pure water, and use a cean syringe to inject water from the inlet until the oxygen outlet water comes out. it is recommended that the electrolyzer be calculated from the factory date, and the best installation is completed within120 days, and the machine inventory time is recommended not to exceed 180days after the installation. lf the machine inventory time is too long, it will cause the MEA inside the electrolyzer to dry out and affect the performance of the electrolyzer. lf the electrolyzer is not stored or used in accordance with the above storage requirements, we have the right to exempt the damaged electrolyzer from liability

Related Products

Product Message

If you are interested in our products, please leave your e-mail, we will contact you as soon as possible, thank you!